Home » Firearms and Shooting » Shotguns » Alofs Reloading Magazine: A Economical Retrofit for Single-Shot Shotguns

Alofs Reloading Magazine: A Economical Retrofit for Single-Shot Shotguns

Craig Mitchell is an Outdoor Education Teacher from Toronto, Canada…

100 years ago, one metalworker named Herman Alofs enabled post-Great Depression shotgunners to reload efficiently without buying a pump-action

The 1920s in America was a tumultuous time. The Great War had recently ended, and the economic impacts and consequences were being felt on the home front. The Great Depression wiped out the financial future of many Americans. Folks now scraped by, making ends meet by using what skills or cost-saving measures they could muster.

The “War to End All Wars” led to many new and exciting innovations, including those in the firearm industry. One of the most noteworthy was the Allies’ use of shotguns in the trenches of Europe. Repeater-style shotguns were so lethal and effective, the German government protested their use at the Geneva Convention. They argued that their efficiency and extreme lethality made them an unfair weapon of war. Fast forward to the 1920s, and word spread about the power of repeater-style shotguns. Imagine what they could do on a covey of quail or flock of ducks!

Unfortunately, for many Americans at the time, the $40-60 price tag on pump-action shotguns was far out of reach. But for one enterprising young metal worker, it sparked an idea. He created an economical and utilitarian shotgun accessory that modernized many old-fashioned break-action shotguns.

Herman Alofs’ Reloading Magazine

Herman Gerrit Alofs was born May 17, 1903, in East Saugatuck, Michigan. Not much is known about the innovative inventor, aside from his being born into a family of Dutch immigrants. He also founded Alofs Manufacturing Company, which specialized in sheet metal production. His innovative designs were born during the flourishing industrial age of the early 20th century.

Whether Herman Alofs was a firearm enthusiast eager to leave his mark on the industry or a capitalist who saw an opportunity is up for debate. Either way, the Great Depression instilled the need for fiscal responsibility in the young industrialist.

Hunters and firearm owners often could not purchase fancy repeating shotguns, including the latest and greatest pump actions. Alofs’ reloading magazine turned single-shot shotguns into repeaters via a tubular magazine. Paired with an affordable and utilitarian single-shot break action shotgun, it significantly upgraded post-Depression hunters’ firepower and harvest rates. For just $6, it allowed users to turn a single-shot into a 5-round repeater (one in chamber, four in magazine). It was an affordable offering that modernized the single-shot shotguns already present on farms and in cabins.

The repeating mechanism could be added to a pre-owned break-action shotgun or coupled with a new single-shot gun for about $16. This combination would outfit its owner for a variety of game for less than a third of the price of a new repeating shotgun. For example, the Winchester 1897 retailed for $42.50 at the time.

How Alofs’ Magazine Worked

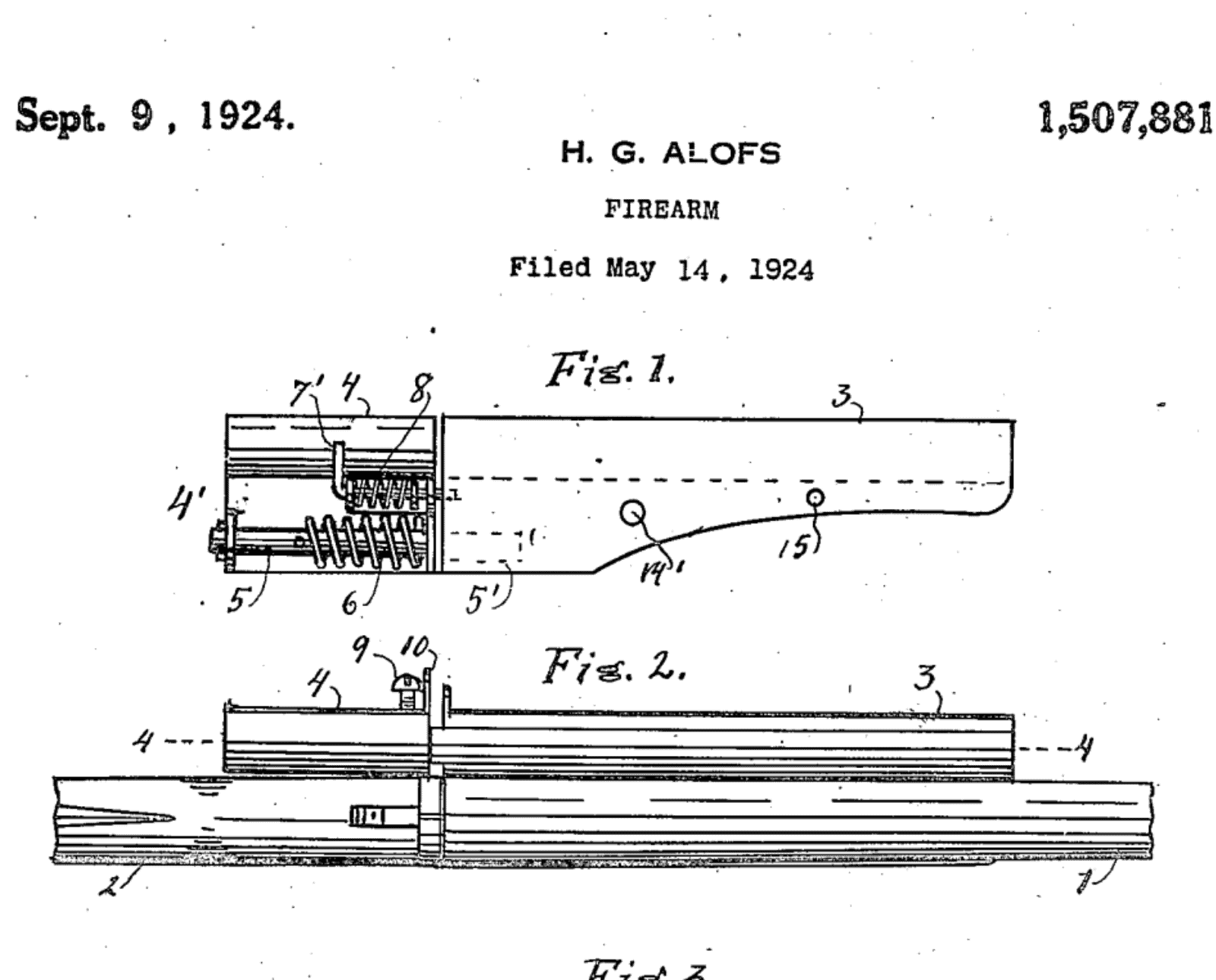

Alofs’ reloading magazine is very Rube Goldberg-ian in nature. It relied on a series of levers, springs, and the force created from the firearm’s ejector to manipulate the reloading device.

The shotgun “cracked” open to eject the empty shell. Then, it’d hit a spring on the Alofs mechanism, triggering it to flip down over the now empty chamber. This movement released and deposited a new shell in the blink of an eye. Shutting the action, just as one would without the device, shifted the magazine back into place. It was on the left-hand side of the action, out of the way of the shooter’s eye.

The device allowed for a single-shot shotgun to carry and fire five rounds and shoot as fast as the user could cock the hammer and pull the trigger.

Alofs Reloading Magazine Gauges

Alofs Manufacturing Company of Grand Rapids, Michigan, patented the device on September 9, 1924, in the United States and Canada. It was frequently paired with Iver Johnson single-shot shotguns made by Canadian manufacturer Cooey Machine and Company.

Alofs Manufacturing Company advertised that the magazine was available in several gauges. This included the .410, 16, 20, and 12 gauges. No known examples exist aside from those chambered in 12 gauge. It is debated whether any magazines were actually manufactured in gauges other than 12. It was more likely they were advertising smaller bores to gauge interest or gain attention to warrant their eventual creation.

Limitations of Alofs’ Reloader

The device’s limitation, compared to more modern repeating shotguns of the time, was its cumbersome and slow reload rate. The reloading gate was also prone to snapping shut on the operator’s thumb. It was akin to the often-talked-about “garand thumb” injury seen with the famous World War II rifle, the M1 Garand.

The Achilles’ heel of this unique feat of engineering was the need to manually cock the hammer before each shot. This left it up to debate as to whether it really was faster to shoot than a single shot. Users also questioned whether it was actually a better option than a single shot when shooting more than its five-round magazine capacity. The first five shots were fast and effective, but it took a while to reload the tubular magazine.

With the creation of more affordable repeating shotguns in pump-action and semi-automatic versions, Alofs’ Repeating Magazine fell by the wayside. Alofs continued to invent and create, turning his attention toward the new seatbelt laws, which led him to develop and manufacture buckles used in cars and other vehicles.

Herman Alofs died on March 10th, 1983, at 79. Alofs Manufacturing was soon dissolved, leaving little to no documentation about the once novel and innovative shotgun accessory. Today, the creation that shares his name is discussed and collected as an example of novelty firearm innovations, with a recent auction selling an example for between $600 and $900. If you’re like Alofs’ customers and interested in a more affordable option, Sulun Arms makes a reproduction for about $300.

Craig Mitchell is an Outdoor Education Teacher from Toronto, Canada who spends his free time hunting and fishing in Northern Ontario with his family and Wirehaired Pointing Griffon named Clover. Before becoming a teacher, Craig was a back country guide and grew up camping and fishing. When he’s not on an adventure with his young family or planning his next upland hunt, you’ll find him introducing his inner city students to the great outdoors.